Very professional approach with an extensive knowledge in his field of expertise. Highly recommend.

NDT testing

NDT is the process of inspecting, testing, or evaluating materials, components or equipment for discontinuities, or differences in characteristics without destroying the serviceability of the part or system.

Rope access NDT

SWA offers IRATA trained rope access technicians to ensure safe access and inspection of all work in high risk locations across Perth metro, regional and offshore.

WHAT OUR

COMPANY

DOES

What Out Company Does

Rope Access Services

All SWA inspectors hold IRATA rope access qualifications and are able to provide a wealth of knowledge on any project from identifying hazards, creating complex rescue plans, planning and performing rescues from confined spaces, heights or over the side of vessels and platforms.

Our Services

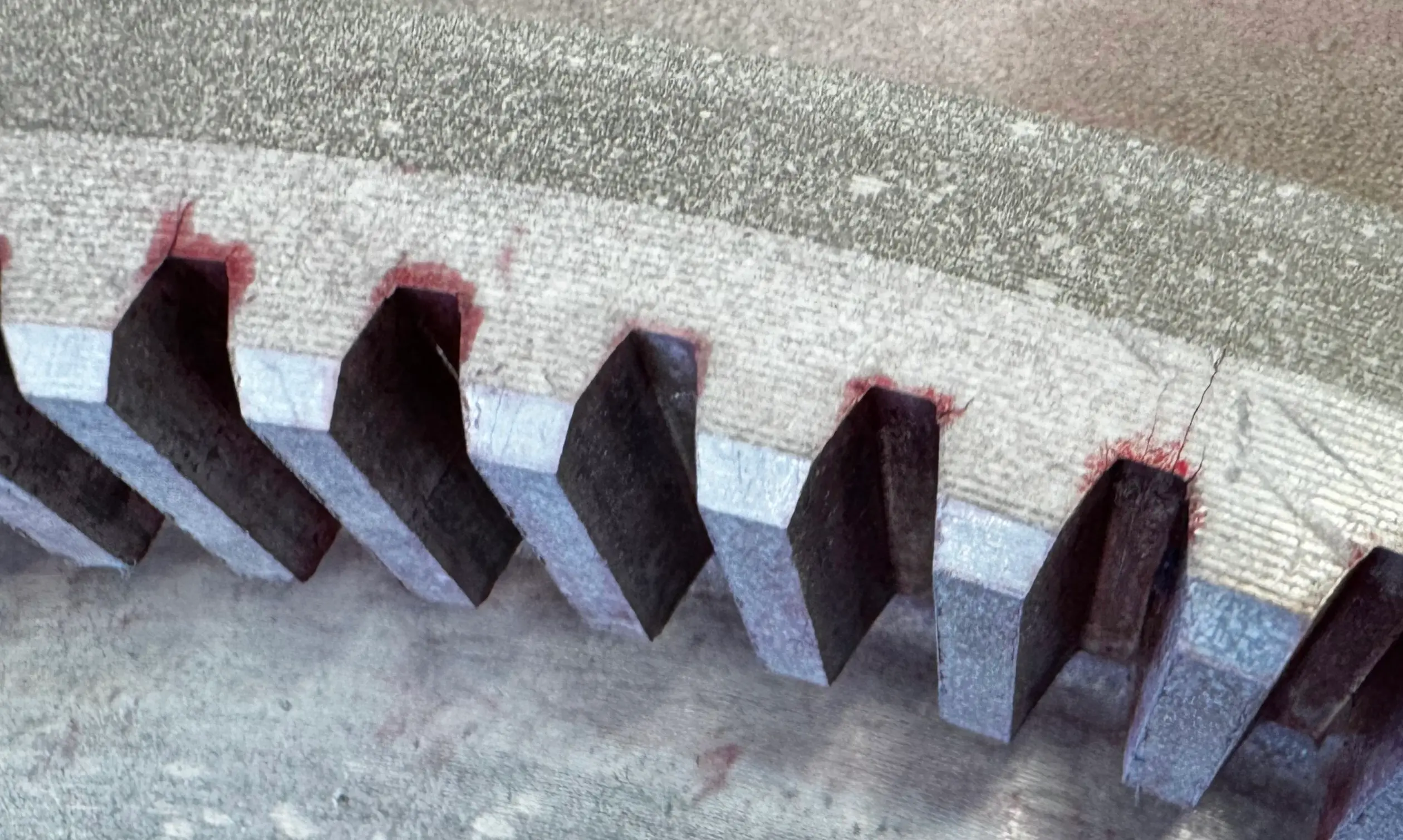

- Magnetic Particle Inspection

- Dye Penetrant Inspection

- Ultrasonic Thickness Testing

- Ultrasonic Weld Testing

- Eddy Current Inspection

Staying Compliant

By using a third party inspection company, you can ensure your plant or equipment complies with relevant laws, regulations and industry standards. This can help prevent costly non-compliance issues and potential legal liabilities.

Our Safety Commitment

SWA is committed to achieving a safety culture of ZERO HARM in the workplace through continuous improvement of safety systems, training and processes. This commitment has been adapted by all personnel and will continue to be a priority as we continue to grow.

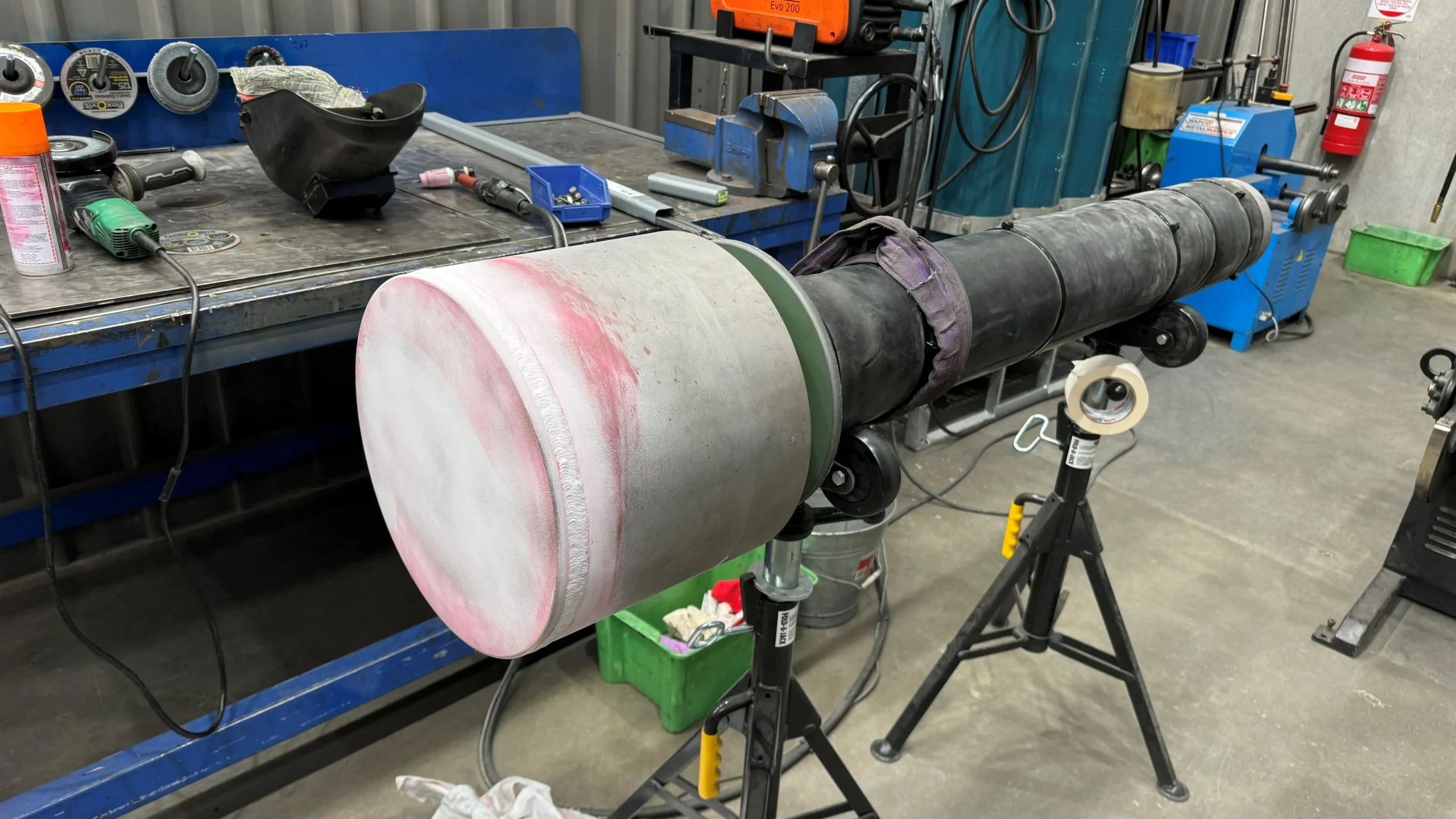

Pipeline Inspection

Weld Integrity Testing: Our MPI services are essential for inspecting pipeline welds, detecting any cracks or defects that could lead to leaks or catastrophic failures.

Corrosion Detection: We help you identify corrosion-related flaws, ensuring the longevity and safety of your pipelines.

Inspection of Pressure Vessels and Storage Tanks

Surface Flaw Detection: We conduct detailed inspections of pressure vessels and storage tanks, detecting surface and near-surface defects that could compromise safety.

Maintenance Inspections: Regular MPI inspections of your tanks and vessels help prevent leaks and ensure compliance with industry safety standards.

Offshore and Subsea Inspections

Inspection of Offshore Structures: Our MPI services extend to offshore platforms, where we inspect critical components for cracks and defects, ensuring structural integrity.

Subsea Equipment Testing: We offer specialised MPI services for subsea equipment, detecting defects without the need for dry conditions.

Drilling Equipment and Rig Inspections

Drill Pipe and Tool Joint Inspections: We provide comprehensive MPI services for drill pipes, tool joints, and other drilling equipment, ensuring they are free from fatigue cracks and other defects.

Rig Structure Testing: Our inspections cover the structural components of drilling rigs, ensuring they can withstand the demanding operational conditions of the oil and gas industry.

Valve and Flange Inspection

Valve Integrity Testing: Our MPI services detect surface defects in valves, ensuring they operate reliably under pressure.

Flange Face Inspection: We inspect flanges to ensure they maintain proper seals in your pipeline systems, preventing leaks and ensuring safety.

Refinery and Plant Equipment Inspection

Heat Exchanger Tube Testing: We inspect heat exchanger tubes and other refinery components for cracks and defects, preventing costly equipment failures.

About Us

SWA are an Australian owned and operated inspection company with extensive experience operating in the oil, gas and mining sectors.

We are determined to provide a quality service with a focus on safety, respect and integrity. In pursuing this goal, we have been granted accreditation to NATA ISO IEC 17025. This has allowed us to ensure the highest quality for our clients and the expectation for employee training and development.

Our Clients

Industries we serve

Oil

Gas

Industrial

Mining

TESTIMONIALS

I could not thank Kieran and his team for their customer service, they responded to our call immediately, and advised the correct service we needed. They came out to our premises same day, carried out the scope of work with great professionalism and sent the report through next day! I couldn’t get any better!

We carry out all of our annual inspections with Kieran at SWA. SWA provides a highly professional service that always goes above and beyond to meet their promises and carry out thorough inspections with prompt response times issuing certifications. Selcouth endorses SWA’s services to the highest extent and can’t recommend them enough – the best in the business!

SWA inspections carry our anchor testing at Red Rope Access training centre in Wangara.

We can not recommend them enough.

SWA were very easy to deal with, received good quality report on completion of job.